Anodized Printing

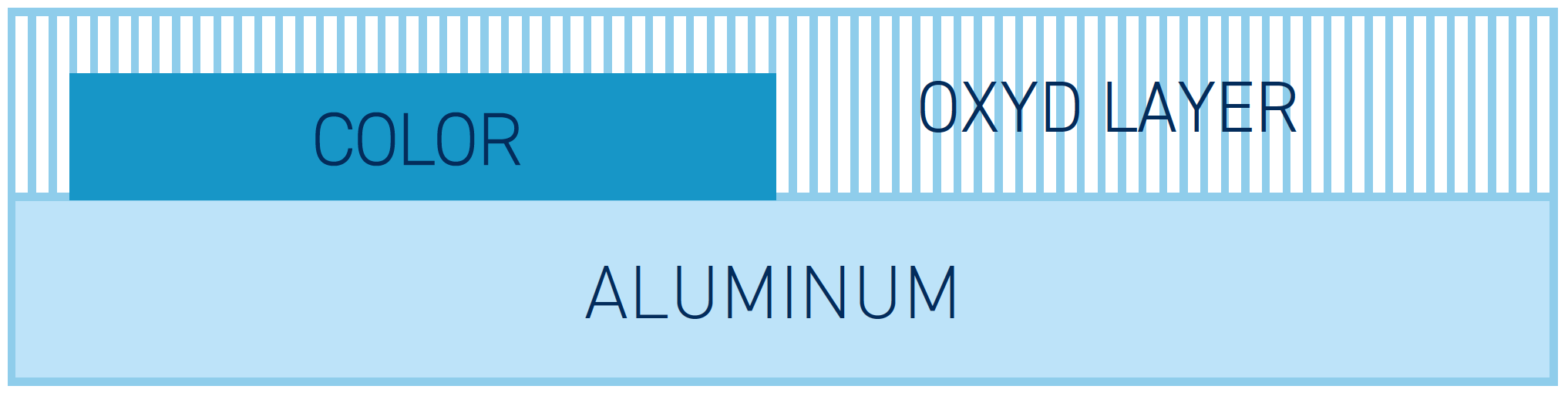

Anodic printing, also called sub-anodic printing or sub-anodic printing, is a printing process that allows printing into the anodized layer of anodized aluminum.

How does it work?

For this purpose, the aluminum is anodized with open pores, and the colors are then applied in screen printing or digital printing. The colors penetrate deep into the open anodized pores.

Finally, the anodized layer is closed again in the compaction process.

Because the sub-anodized print has been embedded in the anodized layer of the aluminum, it is protected from external influences, which brings considerable advantages in many applications.

Applications

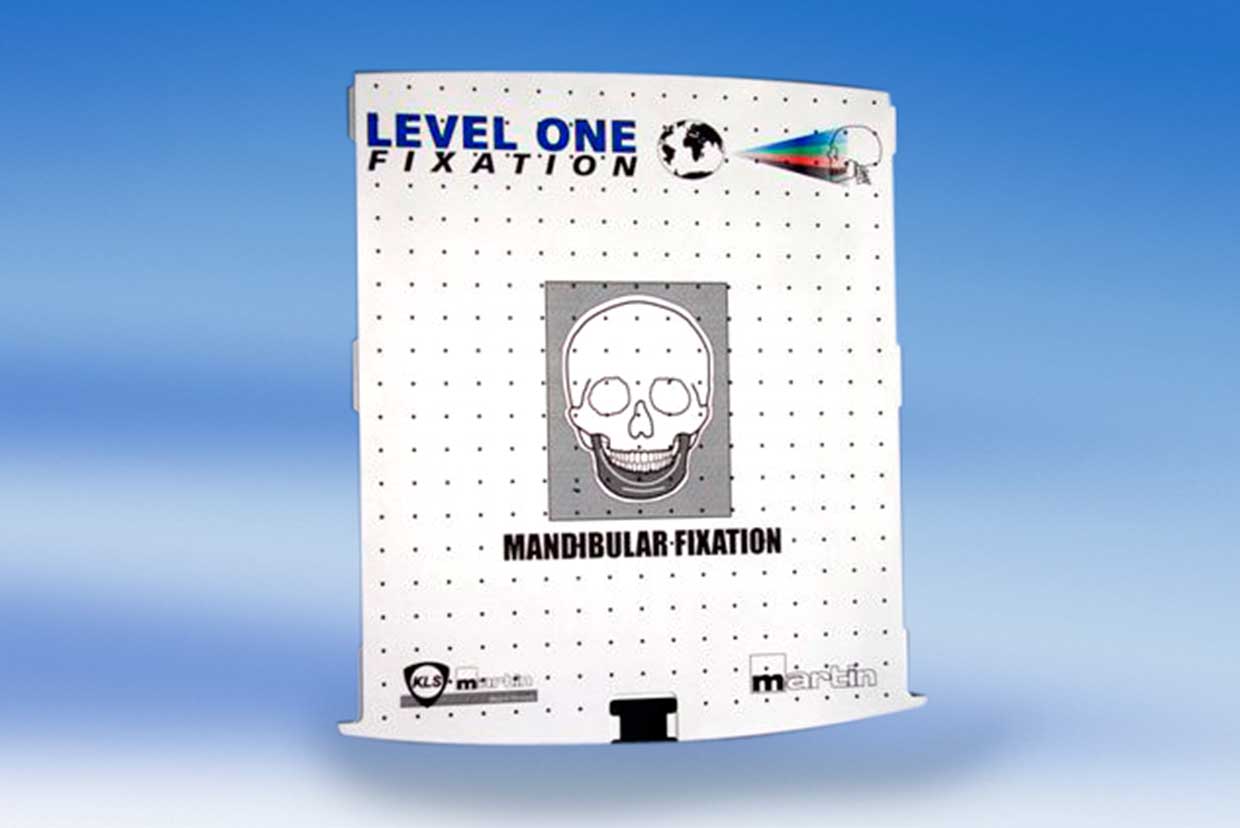

- Sterilization containers

- Front panels

- Scales

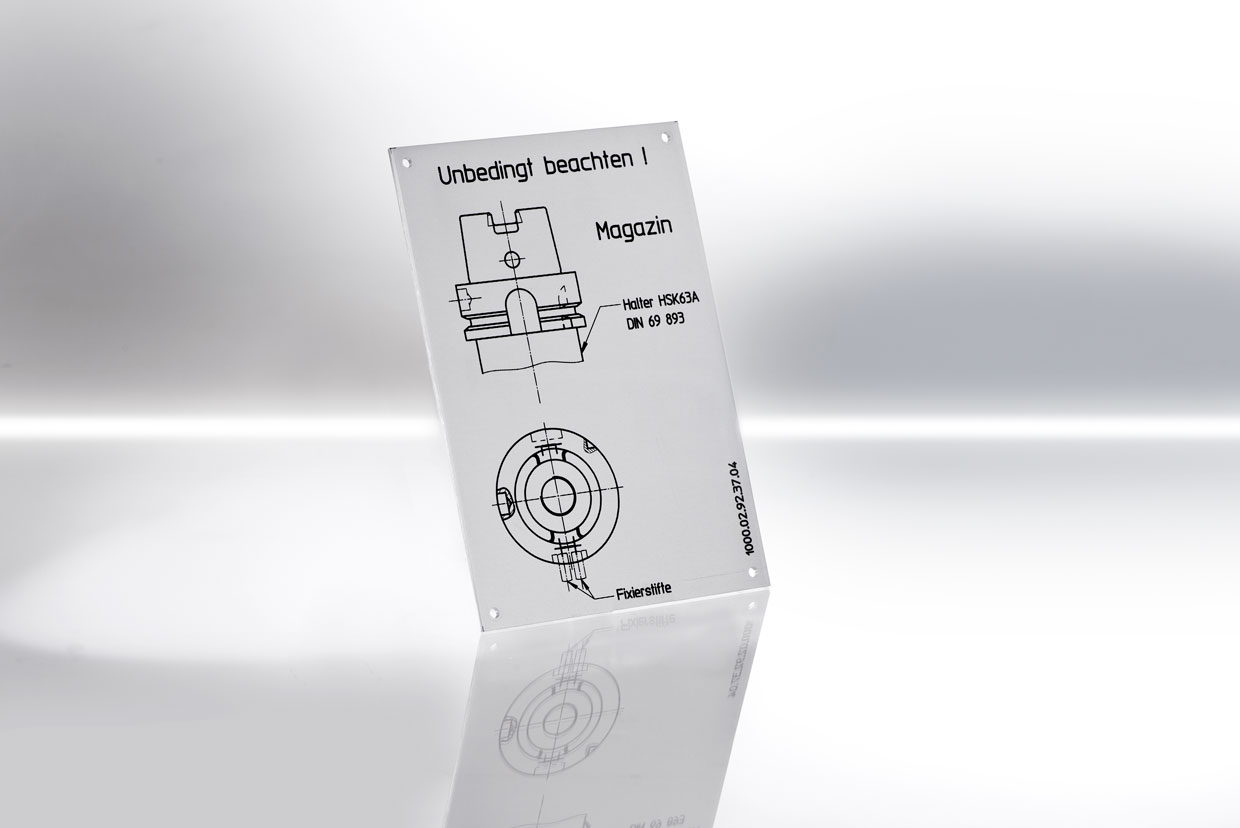

- Machine plates

- Information signs

- Installation parts

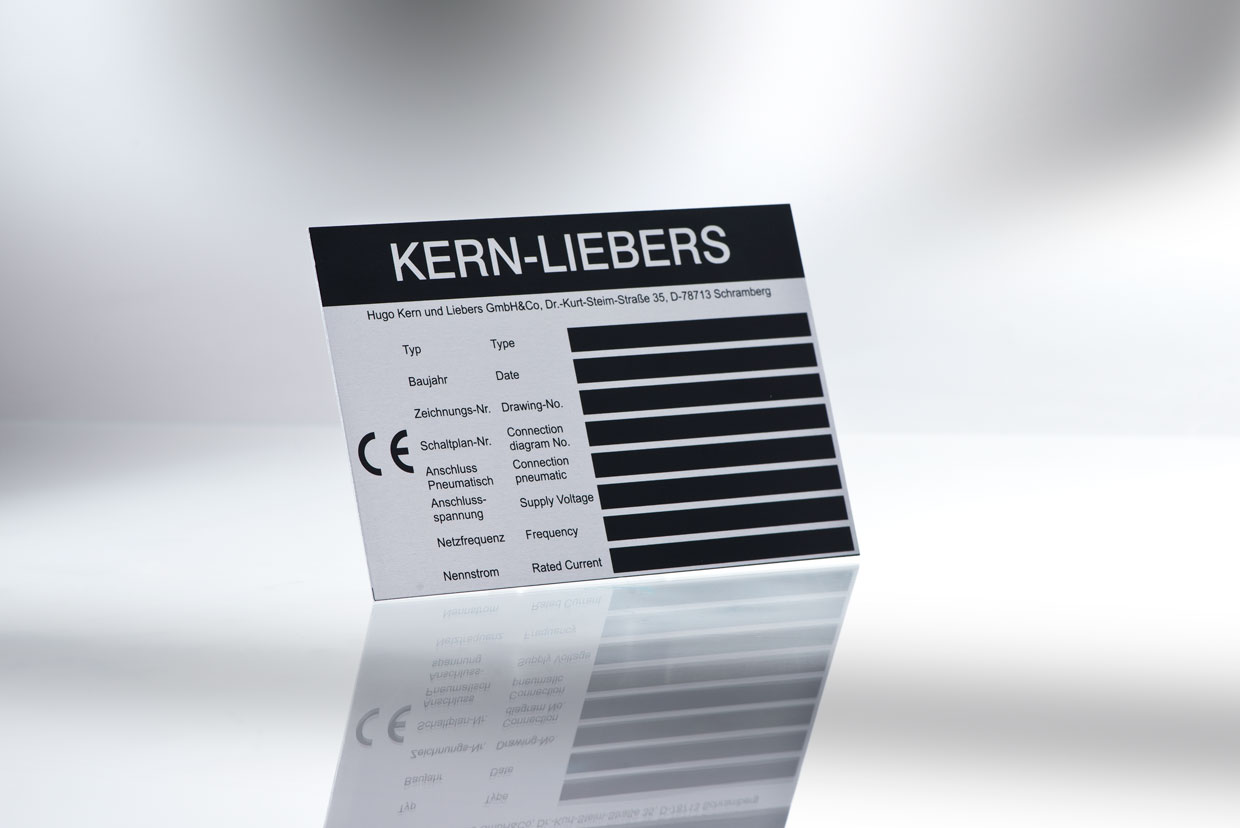

- Company signs

- Identification plates

- Uvm.

Material

- Aluminum

Advantages

- Temperature resistance of the anodized print up to 650°C

- Resistant to chemicals such as nitro, acetone, etc.

- Steam and sterilization resistant

- Scratch resistant against mechanical abrasion

- Resistant to solvents

- Color printing in image quality possible

- Printing of small series or prototypes possible